Fluorocarbon topcoat industrial fluorocarbon paint anti-corrosive finish coatings

Product Description

Fluorocarbon topcoat are unique in that they have a long service life and are weather-resistant for up to 20 years without falling off, cracking or pulverizing. This superior durability makes it a cost-effective, low-maintenance long-term protection solution.

Whether for architectural, industrial or residential use, fluorocarbon finishes offer unmatched performance and reliability, making them the first choice for demanding applications. Trust the advanced technology and proven performance of our fluorocarbon topcoats to protect your surface and keep it in top condition for years to come.

Technical specification

| Appearance of coat | The coating film is smooth and smooth | ||

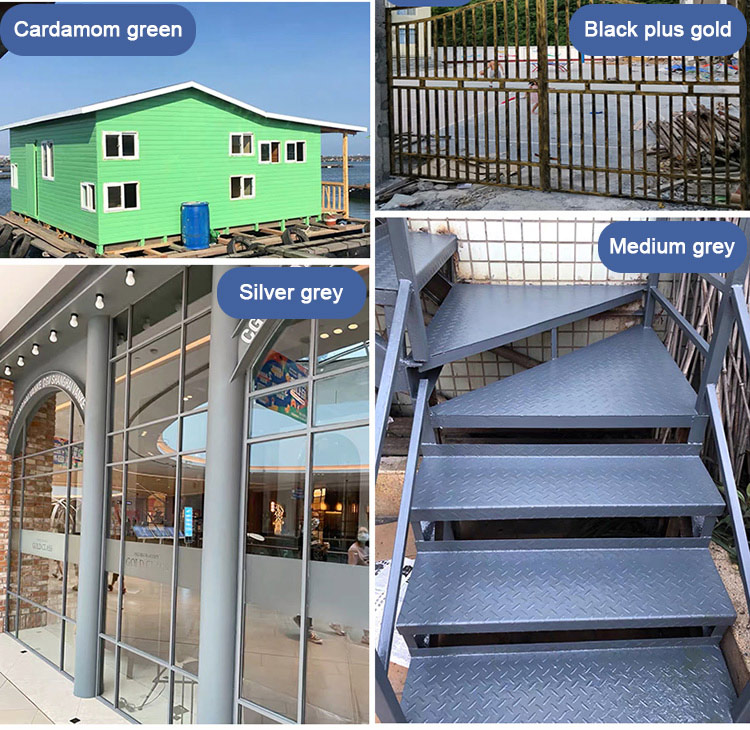

| Color | White and various national standard colors | ||

| Drying time | Surface dry ≤1h (23°C) Dry ≤24 h(23°C) | ||

| Fully cured | 5d (23℃) | ||

| Ripening time | 15min | ||

| Ratio | 5:1 (weight ratio) | ||

| Adhesion | ≤1 level (grid method) | ||

| Recommended coating number | two, dry film 80μm | ||

| Density | about 1.1g/cm³ | ||

| Re-coating interval | |||

| Substrate temperature | 0℃ | 25℃ | 40℃ |

| Time length | 16h | 6h | 3h |

| Short time interval | 7d | ||

| Reserve note | 1, coating after the coating, the former coating film should be dry, without any pollution. 2, should not be in rainy days, foggy days and relative humidity greater than 80% of the case. 3, before use, the tool should be cleaned with diluent to remove possible water. should be dry without any pollution |

||

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

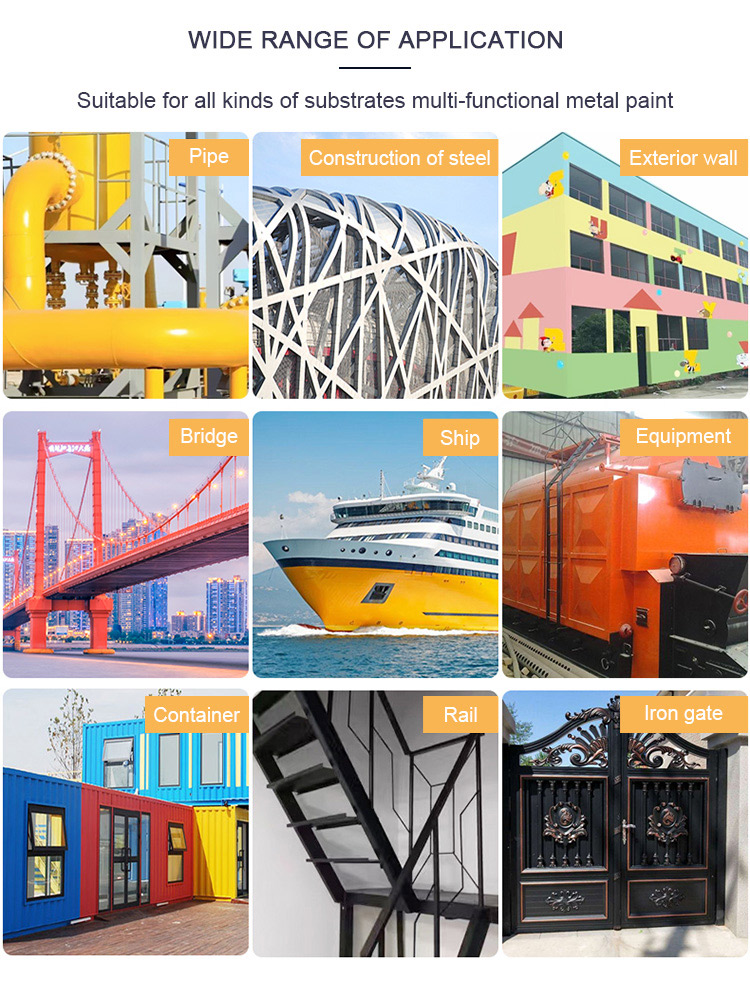

Scope of application

Product features

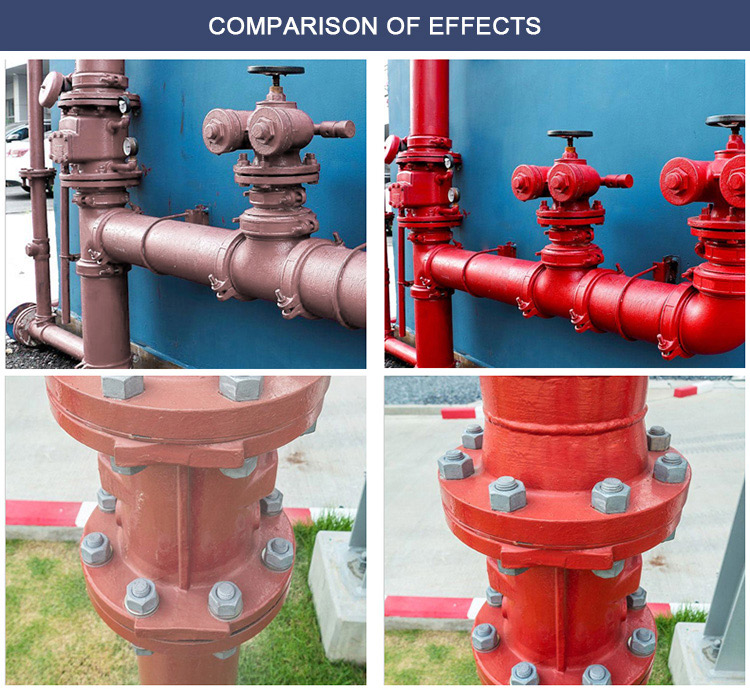

One of the outstanding features of fluorocarbon finish paint is their excellent anti-corrosion and mildew resistance, making them a reliable solution for surfaces exposed to humid environments. In addition, its excellent yellowing resistance ensures that the coated surface retains its original appearance over time.

Chemical stability and high durability are inherent qualities of this finish, ensuring lasting protection against a wide range of substrates. Fluorocarbon topcoat also have UV resistance, making them ideal for outdoor applications that require exposure to sunlight.

Coating method

Construction conditions: The substrate temperature must be higher than 3°C, outdoor construction substrate temperature, below 5°C, epoxy resin and curing agent curing reaction stop, should not be carried out construction.

Mixing: The A component should be stirred evenly before adding the B component (curing agent) to blend, stirring evenly at the bottom, it is recommended to use a power agitator.

Dilution: After the hook is fully matured, an appropriate amount of supporting diluent can be added, stirred evenly, and adjusted to the construction viscosity before use.

Safety measures

The construction site should have a good ventilation environment to prevent the inhalation of solvent gas and paint fog. Products should be kept away from heat sources, and smoking is strictly prohibited at the construction site.

Storage and packaging

Storage: must be stored in accordance with national regulations, the environment is dry, ventilated and cool, avoid high temperature and far from the fire source.

Storage period: 12 months, after the inspection should be used after qualified.