Alkyd enamel paint Universal alkyd quick drying enamel paint Industrial coatings

Product Description

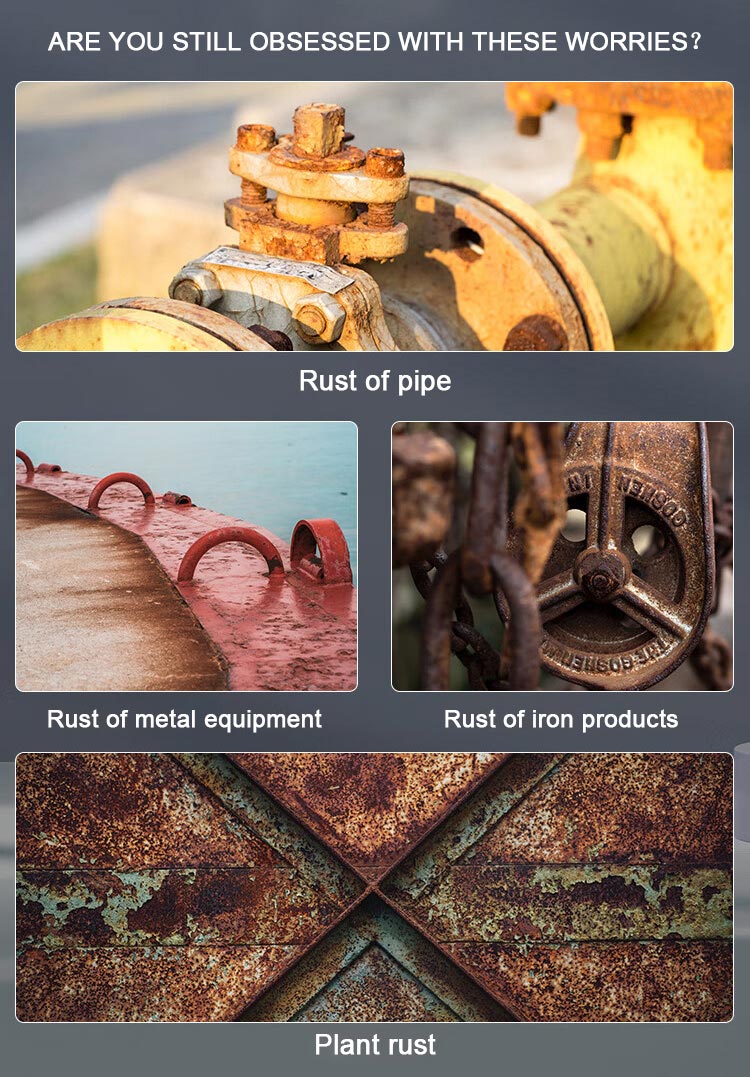

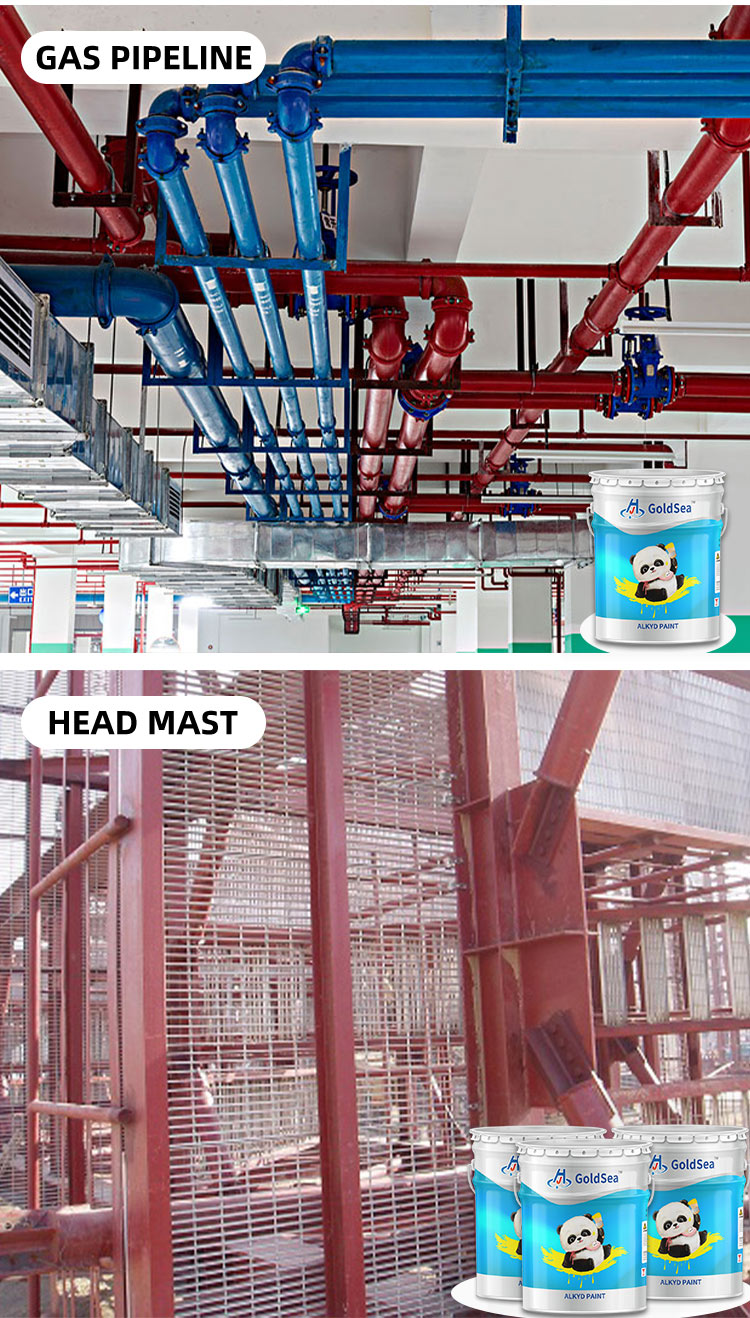

Our alkyd quick-drying enamel dries naturally at room temperature, saving you time and effort during the painting process. The strong paint film it forms ensures a long-lasting and durable surface effect, making it ideal for a variety of applications. Whether you're working on metal, wood or other surfaces, this enamel provides excellent adhesion, ensuring your paint job stays fresh and vibrant for years to come.

Product Features

One of the outstanding features of our quick-drying enamel is its outdoor weather resistance. This makes it a reliable choice for projects that require a high level of durability and weatherproof protection. Whether you are painting outdoor furniture, fences or other exterior surfaces, you can be confident that our enamels will provide a resilient and attractive finish.

In addition to practical benefits, our quick-drying enamel paints also have a beautiful gloss that enhances the overall appearance of your project. The smooth, glossy surface adds a professional touch to any surface, making it a versatile choice for industrial and decorative applications.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | stocked item: 3~7 working-days customized item: 7~20 working days |

Fast drying

Dry quickly, table dry 2 hours, work 24 hours.

Paint film can be customized

Smooth film, high gloss, multi-color optional.

Main Composition

Various kinds of alkyd enamel composed of alkyd resin, dry agent, pigment, solvent, etc.

Main characteristics

Paint film color bright, bright hard, fast drying, etc.

Main Application

Suitable for metal and wood products surface protection and decoration.

Technical index

Project: Index

Container state: There is no hard lump in the mixing, and it is in an even state

Constructability: Spray two barner free

Drying time, h

Surface stem ≤ 10

Work hard ≤ 18

Paint film color and appearance: In line with the standard and its color range, smooth and smooth.

Outflow time(No.6 cup),S ≥ 35

Fineness um ≤ 20

Covering power, g/m

White ≤ 120

Red, yellow ≤150

Green ≤65

Blue ≤85

Black ≤ 45

Non-volatile matter, %

Biack red, blue ≥ 42

Other colors ≥ 50

Mirror gloss (60degree) ≥ 85

Bending resistance (120±3 degree

after 1h heating), mm ≤ 3

Specifications

| Water resistance (immersed in GB66 82 level 3 water). | h 8. no foaming, no cracking, no peeling. Slight whitening is allowed.The gloss retention rate is not less than 80% after immersion. |

| Resistanoe to volatile oil fimmersed in solvent inaccordance with SH 0004, rubber industry). | h 6, no foaming, no cracking. no peeling, allow slight loss of light |

| Weather resistance (measured after 12 months ofnatural exposure in Guangzhou) | The discoloration does not exceed 4 grades, the pulverization does not exceed 3 grades, and the cracking does not exceed 2 grades |

| Storage stability. Grade | |

| Crusts (24h) | Not less than 10 |

| Settleability (50 ±2degree, 30d) | Not less than 6 |

| Solvent soluble phthalic anhydride, % | Not less than 20 |

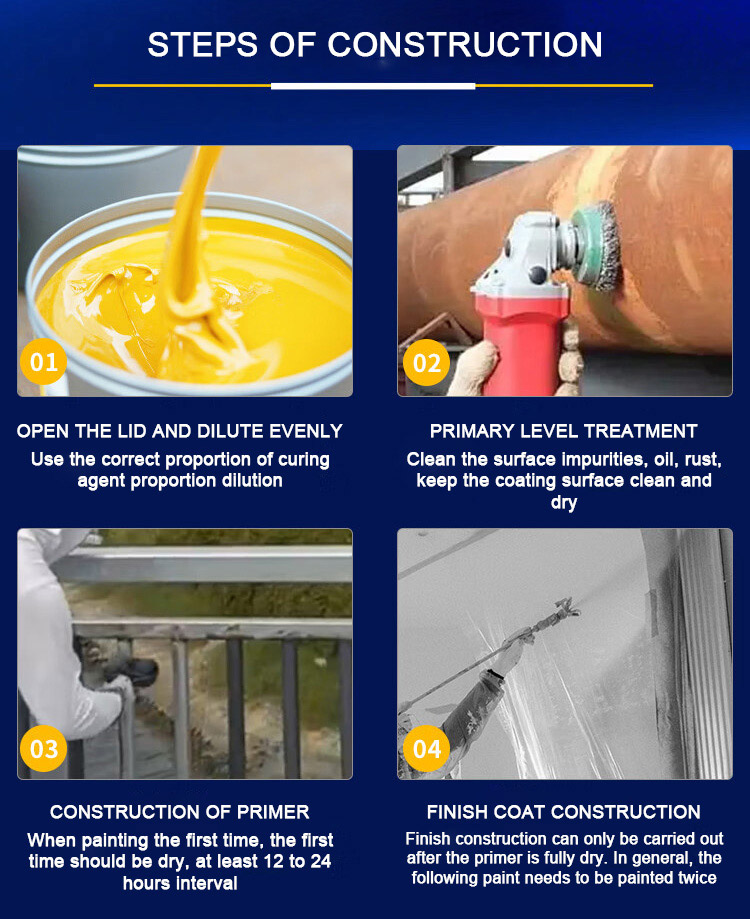

Construction reference

1. Spray brush coating.

2. Before use the substrate will be treated clean, no oil, no dust.

3. The construction can be used to adjust the viscosity of diluent.

4. Pay attention to safety and stay away from fire.