Chlorinated Rubber Primer Paint Anti-Corrosion Coating Boat Industrial Paint

Product Description

Chlorinated rubber primer paint is a common coating whose main components include chlorinated rubber resins, solvents, pigments and additives.

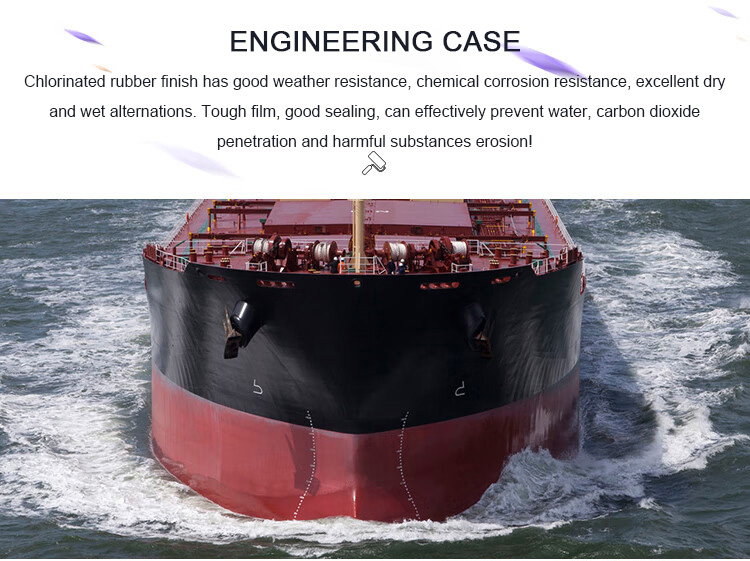

- As the substrate of the paint, chlorinated rubber resin has excellent weather resistance and chemical corrosion resistance, making the paint film stable and durable in the outdoor environment.

- The solvent is used to regulate the viscosity and fluidity of the paint to facilitate construction and painting.

- Pigments are used to give the film the desired color and appearance characteristics, while also providing additional protection and decorative effects.

- Additives are used to regulate the properties of the paint, such as increasing the wear resistance and UV resistance of the coating.

The reasonable proportion and use of these ingredients can ensure that chlorinated rubber paint has excellent weather resistance, chemical resistance and wear resistance, and is suitable for surface protection and decoration of various outdoor and industrial facilities.

Main features

Chlorinated rubber paint has many outstanding characteristics, which makes it widely used in different fields.

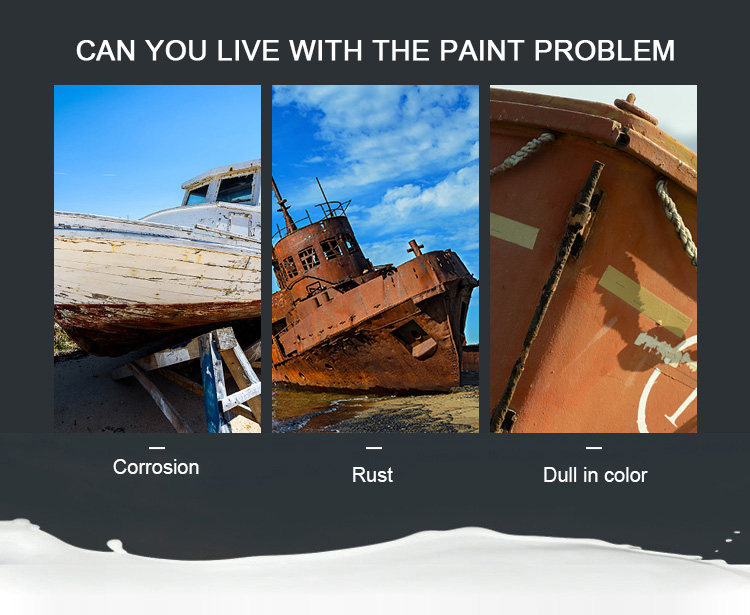

- First of all, chlorinated rubber paint has excellent weather resistance and corrosion resistance, which can maintain the stability and color brightness of the coating in the outdoor environment for a long time.

- Secondly, chlorinated rubber paint has good adhesion and can be firmly attached to various substrate surfaces, including metal, concrete and wood.

- In addition, chlorinated rubber paint is easy to construct, dries quickly, and can form a strong paint film in a short time.

- In addition, chlorinated rubber paint also has good wear resistance and chemical resistance, which is suitable for the protection of various industrial facilities and decorative surfaces.

In general, chlorinated rubber paint has become a widely used coating material because of its weather resistance, corrosion resistance, strong adhesion and convenient construction.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | stocked item: 3~7 working-days customized item: 7~20 working days |

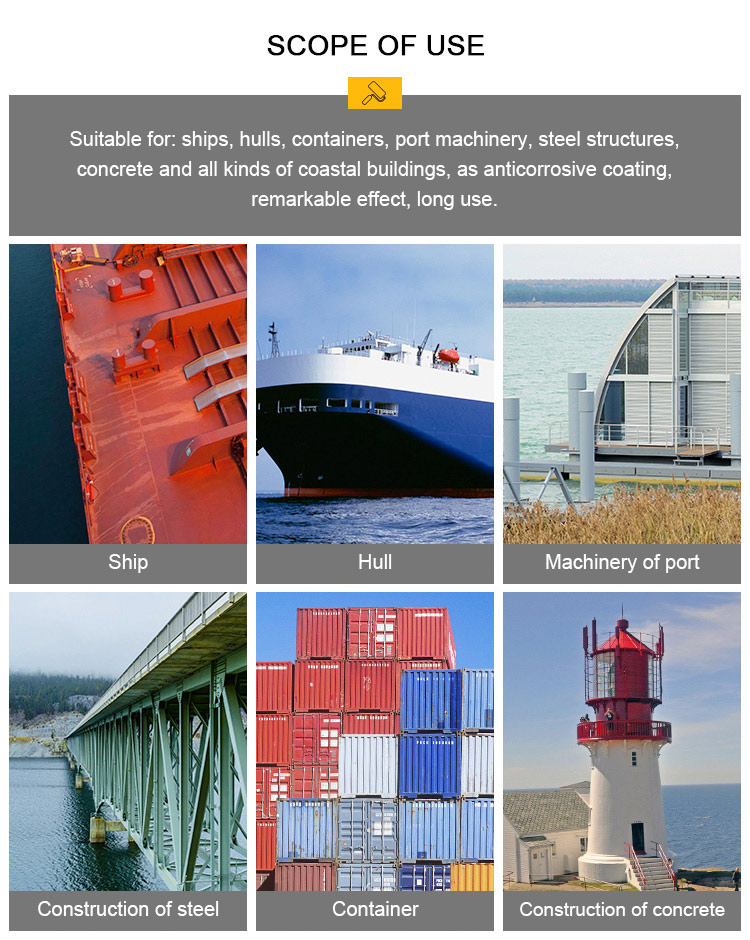

application scene

Chlorinated rubber paint has a wide range of applications in construction, industry and Marine fields.

- In the construction industry, chlorinated rubber paints are often used to paint roofs, walls and floors, providing weather resistance and water protection. Its weather resistance and corrosion resistance make it a common paint in Marine environments for the protection of ships, docks and Marine installations.

- In the industrial field, chlorinated rubber paint is widely used in metal structures, pipelines, storage tanks and chemical equipment surface protection, providing corrosion resistance and wear resistance.

- In addition, chlorinated rubber paint is also commonly used in swimming pools, water tanks and chemical plants waterproof coating, as well as basement and tunnel moisture-proof coating.

In short, the application scenarios of chlorinated rubber paint cover a variety of fields such as construction, industry and Marine, providing weather, anti-corrosion and waterproof protection for various surfaces.

uses

Construction method

Airless spraying is recommended to use 18-21 nozzles.

Gas pressure170~210kg/C.

Brush and roll apply.

Traditional spraying is not recommended.

Diluent special diluent (not exceeding 10% of total volume).

Drying time

Surface dry 25℃≤1h, 25℃≤18h.