Fluorocarbon Coating Primer Paint Metal Structure Industrial Anti-Corrosion Paints

Product Description

Fluorocarbon primer is the primer used in fluorocarbon paint, which generally has good permeability, sealing property, excellent alkaline resistance, acid rain resistance and carbonization resistance, excellent mold resistance, strong adhesion, and can effectively resist the erosion of acid, alkali, salt and other chemicals on the substrate, commonly used is zinc-rich primer and epoxy primer.

In addition, there are also fluorocarbon coating as a primer method, this primer is based on fluorine modified polymer resin as the main base material, adding a variety of corrosion resistant pigments, fillers, additives and solvents, etc., by grinding and dispersing into a group.

Product parameter

| Appearance of coat | The coating film is smooth and smooth | ||

| Color | Various national standard colors | ||

| Drying time | Exterior dry 1h(23°C)Actual drying 24 h(23°C) | ||

| Complete cure | 5d (23°C) | ||

| Ripening time | 15min | ||

| Ratio | 5:1 (weight ratio) | ||

| Adhesion | ≤1 level (grid method) | ||

| Recommended coating number | wet by wet, dry film thickness 80-100μm | ||

| Density | about 1.1g/cm³ | ||

| Re-coating interval | |||

| Substrate temperature | 0℃ | 25℃ | 40℃ |

| Short time interval | 16h | 6h | 3h |

| Time length | 7d | ||

| Reserve note | 1, after coating before coating, the former coating film should be dry, without any pollution. 2, it is not suitable for construction in rainy days, foggy days and relative humidity greater than 80%. 3, before use, the tool should be cleaned with diluent to remove possible water. |

||

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

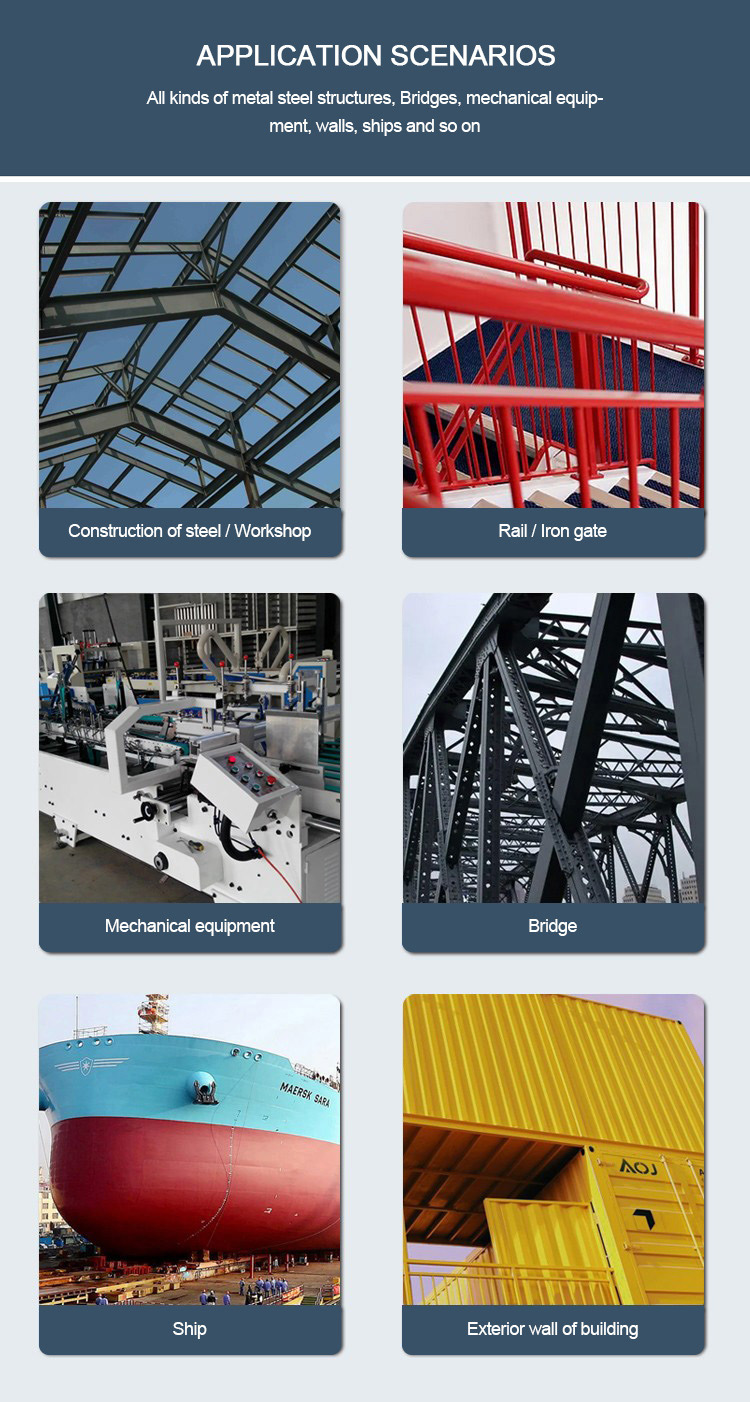

Scope of application

Product features

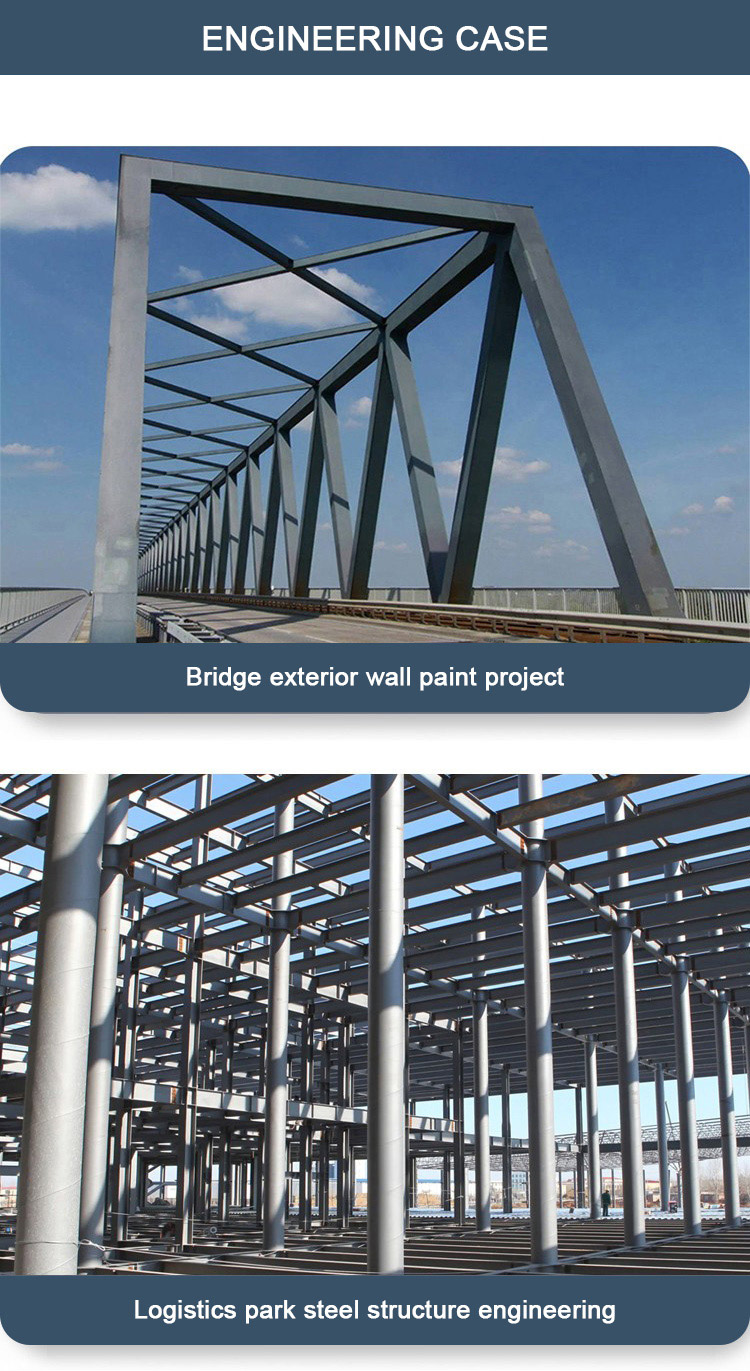

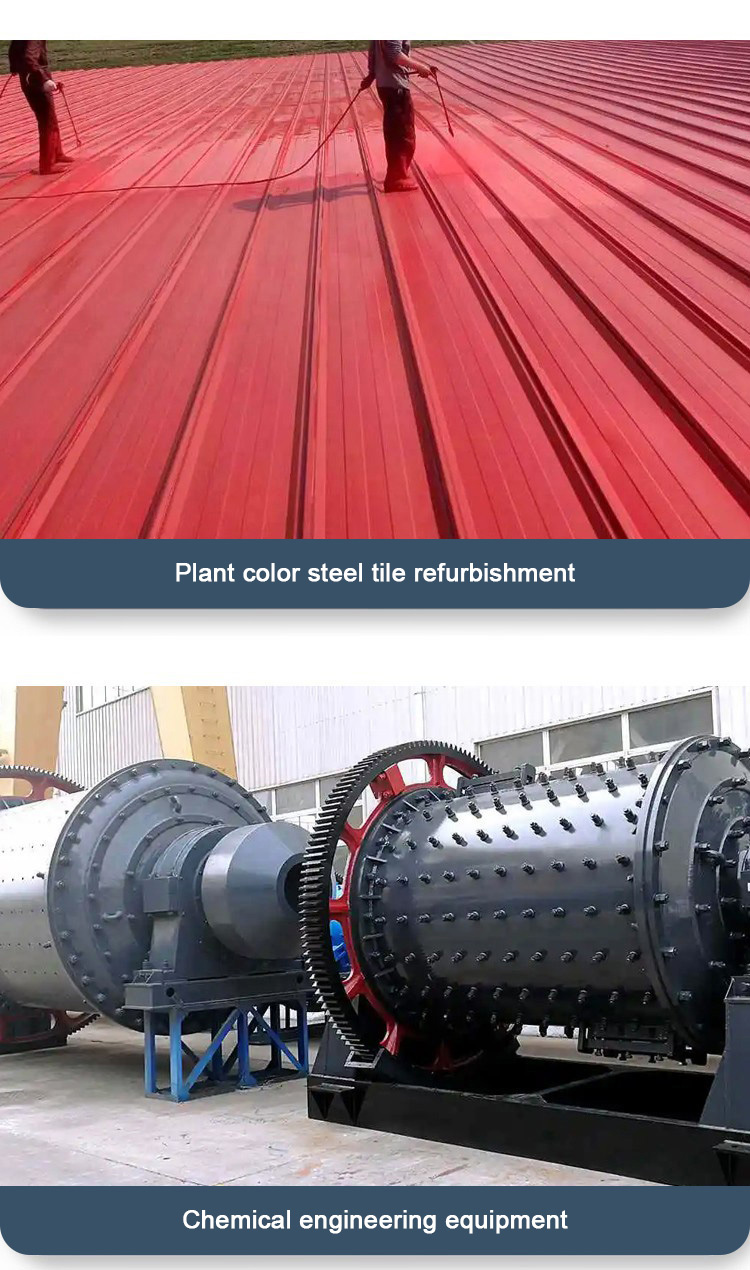

- Excellent corrosion resistance: Thanks to excellent chemical inertness, paint film resistance to acid, alkali, gasoline, salt and other chemical substances and chemical solvents, to provide a protective barrier for the substrate; The film is tough - high surface hardness, impact resistance, resistance to buckling, wear resistance, showing excellent physical and mechanical properties, is now widely used in Bridges, oceans, coastal areas and other heavy anti-corrosion fields.

- Maintenance-free, self-cleaning: fluorocarbon coating has very low surface energy, surface dust can be cleaned by rain, excellent hydrophobicity, oil repellent, minimal friction coefficient, will not adhere to dust and scale, good anti-fouling, paint film lasting as new.

- Strong adhesion: in copper, stainless steel and other metals, polyester, polyurethane, vinyl chloride and other plastics, cement, composite materials and other surfaces have its excellent adhesion, basically showing that it should be attached to any material characteristics.

Coating method

Construction conditions: The substrate temperature must be higher than 3°C dew point, outdoor construction substrate temperature, below 5°C, epoxy resin and curing agent curing reaction stop, should not be carried out construction

Mixing: should first stir the A component evenly and then add the B component (curing agent) to blend, thoroughly stir evenly, it is recommended to use a power.

Mixer to dilute: After mixing evenly and fully curing, you can add an appropriate amount of supporting diluent, stir evenly, adjust to the construction viscosity before use.

About us

Our company has always been adhering to the "'science and technology, quality first, honest and trustworthy , strictimplementation of ls0900l:.2000 international quality management system.Our rigorous managementtechnologicdinnovation, quality service cast the quality of products, won the recognition of the majority of users.As a professionastandard and strong Chinese factory, we can provide samples for customers who want to buy, if you need acrylicroad marking paint, please contact us.