Anti-corrosion Coating Strong Adhesion Chlorinated Rubber Primer Paint

Product Description

Chlorinated rubber primer is formulated from chlorinated rubber, a chemically inert film-forming substance with excellent resistance to moisture, salt, acid, alkali and corrosive gases. This unique composition ensures that the primer provides lasting protection against a variety of environmental and chemical factors, making it suitable for use in harsh environments such as offshore drilling and oil production equipment.

Main features

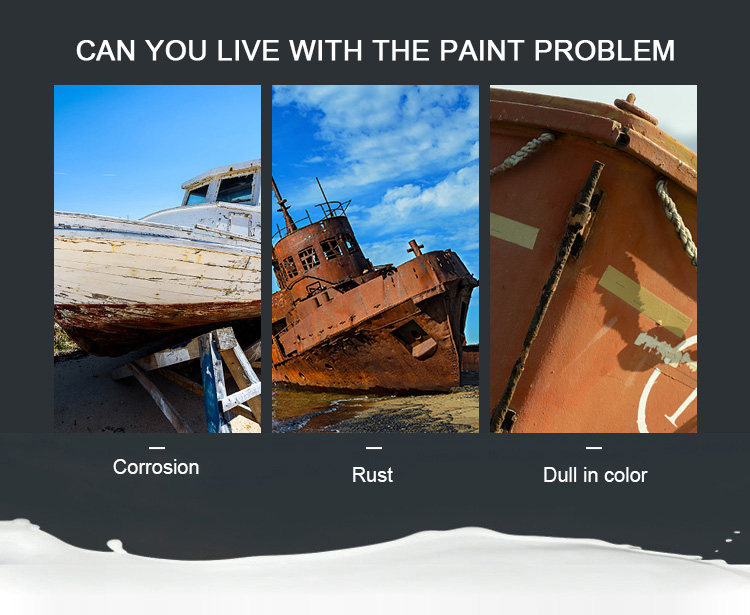

- One of the main characteristics of chlorinated rubber primers is their quick-drying properties, which allow for fast and efficient construction, reduced downtime and increased productivity. Its high hardness and strong adhesion characteristics ensure a durable protective coating that provides reliable protection for containers, vehicle chassis and other industrial equipment.

- In addition to its excellent protective properties, chlorinated rubber primers have excellent resistance to a wide range of corrosives, making them a versatile solution for a variety of industrial applications. Its ability to withstand harsh conditions and corrosive environments makes it ideal for industries where durability and reliability are critical。

- Whether you want to protect containers, offshore equipment or vehicle chassis, chlorinated rubber primers are the perfect choice to provide long-lasting, high-performance protection. Its unique combination of fast drying, high hardness, strong adhesion and corrosion resistance makes it a valuable addition to any industrial coating system.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | stocked item: 3~7 working-days customized item: 7~20 working days |

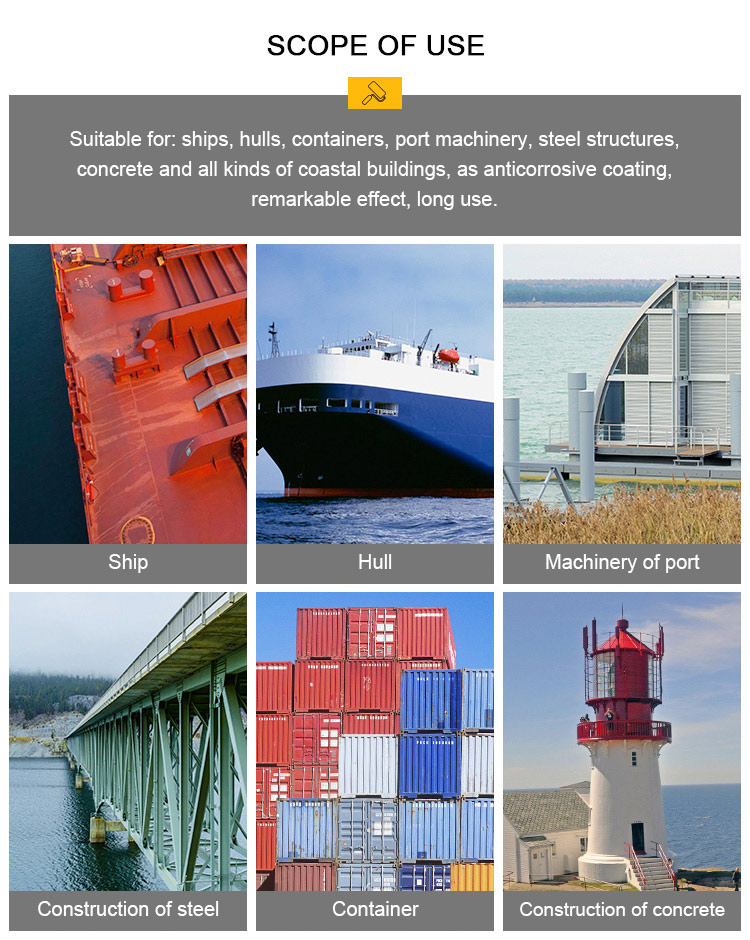

uses

Construction method

Airless spraying is recommended to use 18-21 nozzles.

Gas pressure170~210kg/C.

Brush and roll apply.

Traditional spraying is not recommended.

Diluent special diluent (not exceeding 10% of total volume).

Drying time

Surface dry 25℃≤1h, 25℃≤18h.

Surface treatment

The coated surface must be clean, dry, cement wall first for the bottom filling mud. Chlorinated rubber old paint to remove loose paint leather directly applied.

Front matching

Epoxy zinc-rich primer, epoxy red lead primer, epoxy iron intermediate paint.

After matching

Chlorinated rubber topcoat, acrylic topcoat.

Storage life

The effective storage life of the product is 1 year, expired can be checked according to the quality standard, if meet the requirements can still be used.

Note

1. Before use, adjust the paint and diluent according to the required ratio, match how much to use stir evenly before use.

2. Keep the construction process dry and clean, and do not contact with water, acid, alkali, etc

3. The packing bucket must be tightly covered after painting to avoid gelling.

4. During construction and drying, the relative humidity shall not be greater than 85%, and the product shall be delivered 2 days after coating.