Epoxy anti-corrosion finish paint various colors top-coat high hardness epoxy coating

Use

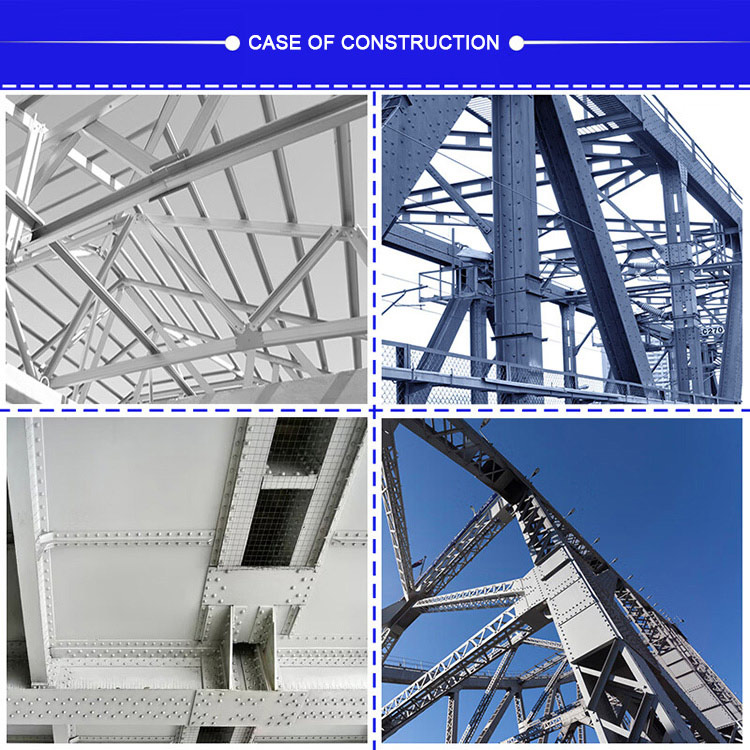

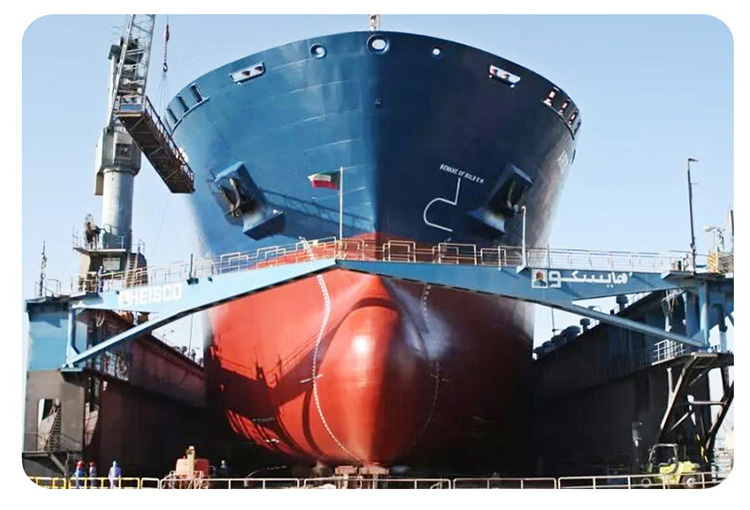

Epoxy top-coat is used as epoxy zinc-rich, inorganic zinc-rich primer and epoxy intermediate paint, as a high anti-corrosive performance of the paint used as a matching finish, used for ships, mining machinery, offshore facilities and other places with high anti-corrosive requirements.

Supporting

Previous supporting: epoxy zinc-rich primer, inorganic zinc-rich primer, epoxy intermediate paint, etc.

Epoxy paint various colors is applied to mechanical equipment Steel structure, aircraft, ships,Chemical plants, machinery, oil tanks, FRP, iron towers. The colors of the floor paint is customized. The main color are white, gray, yellow and red. The material is coating and the shape is liquid. The packaging size of the paint is 4kg-20kg. Its characteristics are corrosion resistance, weathering resistance and high hardness.

Front matching

Epoxy zinc-rich primer, inorganic zinc-rich primer, epoxy intermediate paint, etc.

Before construction, the substrate surface must be clean and dry without any pollution; The substrate is sandblasted to Sa2.5 level with surface roughness of 40-75um.

Product parameter

| Appearance of coat | The film is smooth and smooth | ||

| Color | Various national standard colors | ||

| Drying time | Surface dry ≤5h (23°C) Dry ≤24 h(23°C) | ||

| Fully cured | 7d(23°C) | ||

| Curing time | 20min (23°C) | ||

| Ratio | 4:1 (weight ratio) | ||

| Adhesion | ≤1 level (grid method) | ||

| Recommended coating number | 1-2, dry film thickness 100μm | ||

| Density | about 1.4g/cm³ | ||

| Re-coating interval | |||

| Substrate temperature | 5℃ | 25℃ | 40℃ |

| Time length | 36h | 24h | 16h |

| Short time interval | No limit (no zinc salt formed on the surface) | ||

| Reserve note | There is no powder and other pollutants on the surface of the coating, generally no long coating limitation, before the front coating film is completely cured before coating the second coating is conducive to obtaining better inter layer bonding force, otherwise attention should be paid to the cleaning of the front coating film surface, and if necessary, hair treatment should be taken to obtain good inter layer bonding force. | ||

Product features

Two component, good gloss, high hardness, good adhesion, chemical resistance, corrosion resistance, organic solution resistance, corrosion resistance, moisture resistance, anti-static, tough paint film, impact resistance, collision resistance, etc.

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

Coating method

Construction conditions: The substrate temperature must be higher than 3° C. When the substrate temperature is lower than 5°C, the curing reaction of epoxy resin and curing agent will stop, and the construction should not be carried out.

Mixing: The A component should be stirred evenly before adding the B component (curing agent) to blend, thoroughly stirred, it is recommended to use a power agitator.

Dilution: After the hook is fully matured, an appropriate amount of supporting diluent can be added, stirred evenly, and adjusted to the construction viscosity before use.

Safety measures

The construction site should have a good ventilation environment to prevent the inhalation of solvent gas and paint fog. Products should be kept away from heat sources, and smoking is strictly prohibited at the construction site

First aid method

Eyes: If the paint spills into the eyes, wash immediately with plenty of water and seek medical attention in time.

Skin: If the skin is stained with paint, wash with soap and water or use an appropriate industrial cleaning agent, do not use large amounts of solvents or thinners.

Suction or ingestion: Due to the inhalation of a large amount of solvent gas or paint mist, should immediately move to the fresh air, loosen the collar, so that it gradually recover, such as ingestion of paint please seek medical attention immediately.

Storage and packaging

Storage: must be stored in accordance with national regulations, the environment is dry, ventilated and cool, avoid high temperature and away from fire.