Fluorocarbon Primer Paint Marine Metal Structure Industrial Anti-Corrosion Coating

Product Description

Fluorocarbon primer is a two-component coating prepared by fluorocarbon resin, weather-resistant filler, various auxiliaries, aliphatic isocyanate curing agent (HDI), etc. Excellent resistance to water and heat, excellent resistance to chemical corrosion. Excellent resistance to aging, powdering and UV. Paint film hard, with impact resistance, wear resistance. Good adhesion, compact film structure, with good oil and solvent resistance. Has a very strong light and color retention, decorative good.

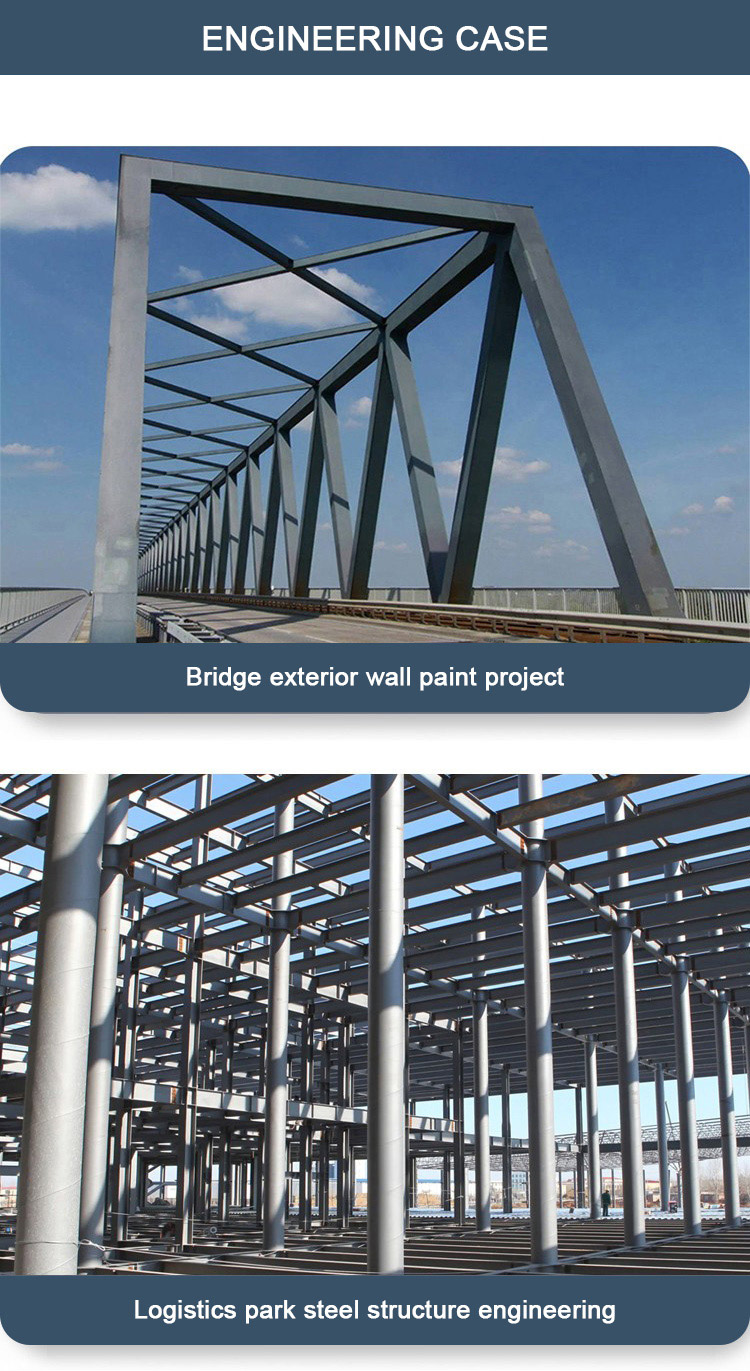

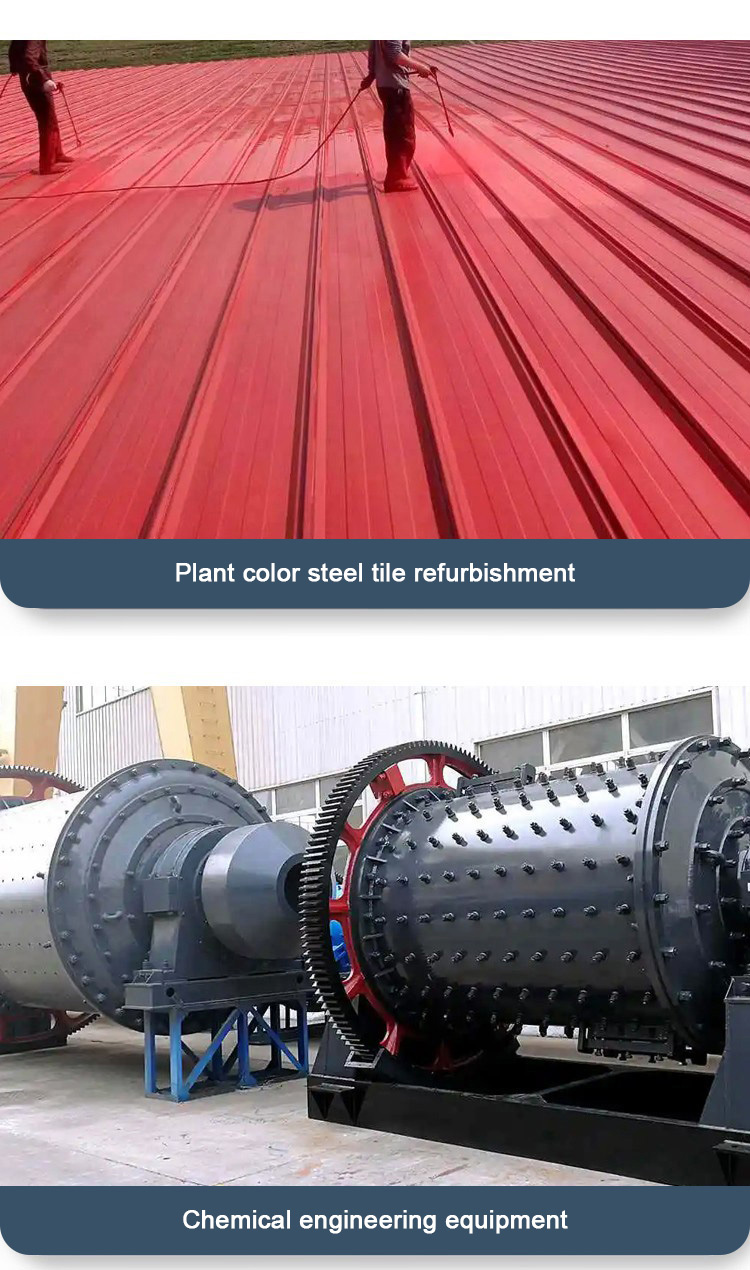

Fluorocarbon primer paint is applied to Machinery, chemical industry, aerospace, buildings, advanced instruments and equipment, vehicles Bridge, vehicle, military industry. The colors of the primer paint are gray,white and red. Its characteristics are corrosion resistance. The material is coating and the shape is liquid. The packaging size of the paint is 4kg-20kg.

Product parameter

| Appearance of coat | The coating film is smooth and smooth | ||

| Color | Various national standard colors | ||

| Drying time | Exterior dry 1h(23°C)Actual drying 24 h(23°C) | ||

| Complete cure | 5d (23°C) | ||

| Ripening time | 15min | ||

| Ratio | 5:1 (weight ratio) | ||

| Adhesion | ≤1 level (grid method) | ||

| Recommended coating number | wet by wet, dry film thickness 80-100μm | ||

| Density | about 1.1g/cm³ | ||

| Re-coating interval | |||

| Substrate temperature | 0℃ | 25℃ | 40℃ |

| Short time interval | 16h | 6h | 3h |

| Time length | 7d | ||

| Reserve note | 1, after coating before coating, the former coating film should be dry, without any pollution. 2, it is not suitable for construction in rainy days, foggy days and relative humidity greater than 80%. 3, before use, the tool should be cleaned with diluent to remove possible water. |

||

Product Specifications

| Color | Product Form | MOQ | Size | Volume /(M/L/S size) | Weight/ can | OEM/ODM | Packing size/ paper carton | Delivery Date |

| Series color/ OEM | Liquid | 500kg | M cans: Height: 190mm, Diameter: 158mm, Perimeter: 500mm,(0.28x 0.5x 0.195) Square tank: Height: 256mm, Length: 169mm, Width: 106mm,(0.28x 0.514x 0.26) L can: Height: 370mm, Diameter: 282mm, Perimeter: 853mm,(0.38x 0.853x 0.39) |

M cans: 0.0273 cubic meters Square tank: 0.0374 cubic meters L can: 0.1264 cubic meters |

3.5kg/ 20kg | customized accept | 355*355*210 | Stocked item: 3~7 working-days Customized item: 7~20 working days |

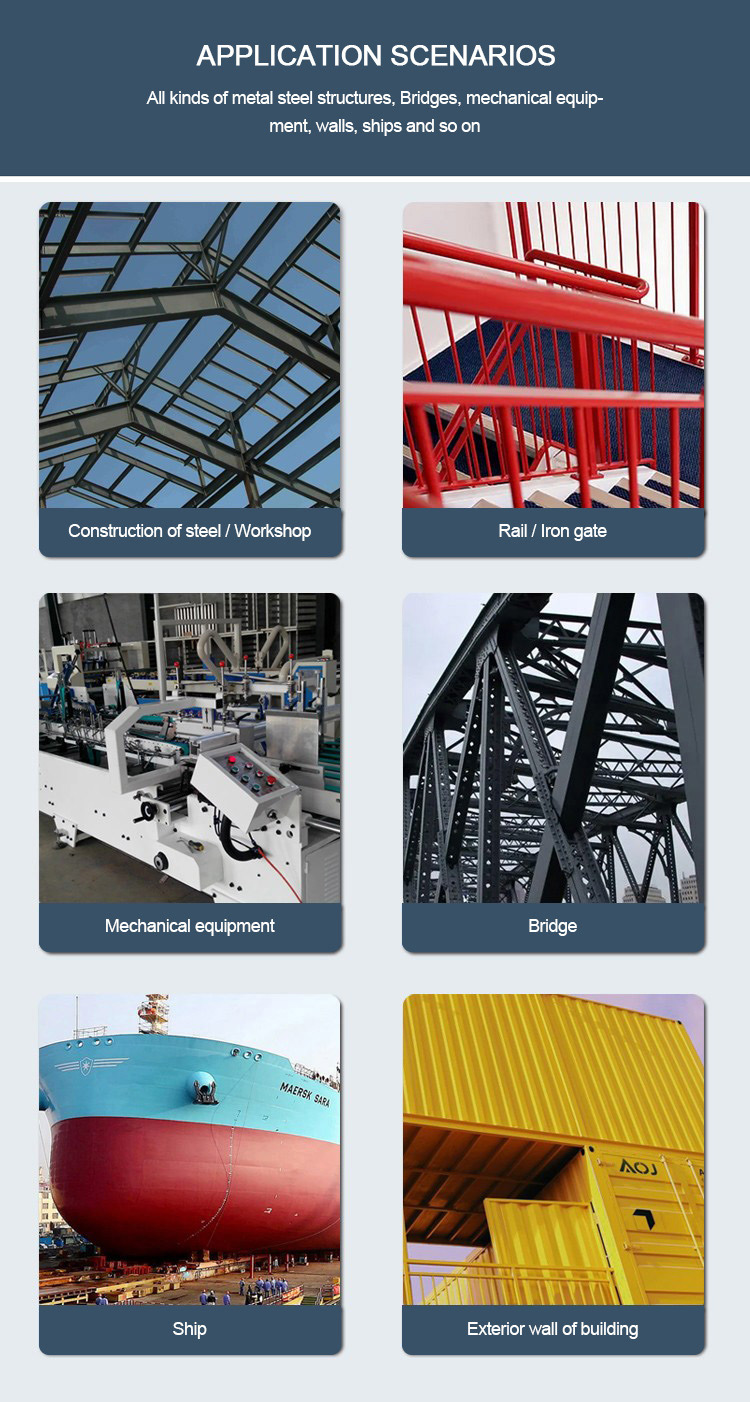

Scope of application

Product features

Fluorocarbon primer has strong adhesion, bright luster, excellent weather resistance, excellent corrosion and mildew resistance, excellent yellowing resistance, chemical stability, extremely high durability and UV resistance, no falling off, no cracking, no chalking, high coating hardness, excellent alkali resistance, acid resistance and water resistance.

Coating method

Construction conditions: The substrate temperature must be higher than 3°C dew point, outdoor construction substrate temperature, below 5°C, epoxy resin and curing agent curing reaction stop, should not be carried out construction

Mixing: should first stir the A component evenly and then add the B component (curing agent) to blend, thoroughly stir evenly, it is recommended to use a power.

Mixer to dilute: After mixing evenly and fully curing, you can add an appropriate amount of supporting diluent, stir evenly, adjust to the construction viscosity before use.

Safety measures

The construction site should have a good ventilation environment to prevent the inhalation of solvent gas and paint fog. Products should be kept away from heat sources, and smoking is strictly prohibited at the construction site.

First aid method

Eyes: If the paint spills into the eyes, wash immediately with plenty of water and seek medical attention in time.

Skin: If the skin is stained with paint, wash with soap and water or use an appropriate industrial cleaning agent, do not use large amounts of solvents or thinners.

Suction or ingestion: Due to the inhalation of a large amount of solvent gas or paint mist, should immediately move to the fresh air, loosen the collar, so that it gradually recover, such as ingestion of paint please seek medical attention immediately.

Storage and packaging

Storage: must be stored in accordance with national regulations, the environment is dry, ventilated and cool, avoid high temperature and away from fire.