Yc-8101a High-temperature Non-stick Porcelain Nano-composite Ceramic Coating (Black)

Product components and appearance

(Two-component ceramic coating)

YC-8101A-A: Component A coating

YC-8101A-B: B component curing agent

YC-8101 colors: transparent, red, yellow, blue, white, etc. Color adjustment can be made according to customer requirements

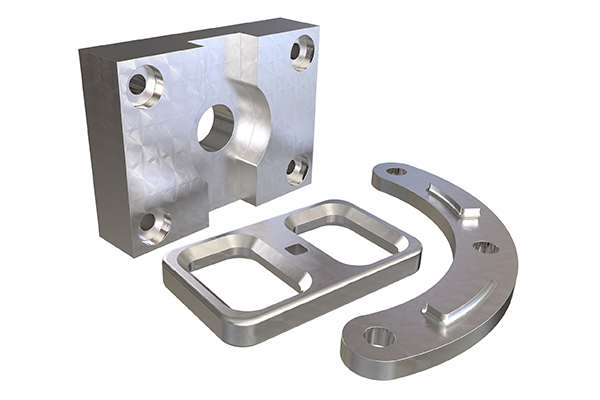

Applicable substrate

The surfaces of various substrates such as non-stick pans can be made of iron, soft steel, carbon steel, stainless steel, aluminum alloy, titanium alloy, high-temperature alloy steel, microcrystalline glass, ceramics, and other alloys.

Applicable temperature

- The maximum temperature resistance is 800℃, and the long-term operating temperature is within 600℃. It is resistant to direct erosion by flames or high-temperature gas flows.

- The temperature resistance of the coating will vary accordingly depending on the temperature resistance of different substrates. Resistant to cold and heat shock and thermal vibration.

Product features

- 1. Nano-coatings are purely water-based, safe, environmentally friendly and non-toxic.

- 2. Nano-composite ceramics achieve dense and smooth vitrification at a low temperature of 250℃, which is energy-saving and aesthetically pleasing.

- 3. Chemical resistance: Heat resistance, acid resistance, alkali resistance, insulation, high-temperature resistance, and resistance to chemical products, etc.

- 4. The coating is resistant to high temperatures and thermal shock within a certain thickness (about 30 microns), and has good thermal shock resistance (resistant to thermal exchange, and does not crack or peel off during the service life of the coating).

- 5. The nano-inorganic coating is dense and has stable electrical insulation performance, with an insulation withstand voltage of about 1000 volts.

- 6. It has stable and good thermal conductivity and excellent bonding strength.

- 7. Hardness: 9H, resistant to open flames and high temperatures up to 400 degrees, high gloss, and high wear resistance

Application fields

1. Boiler components, pipes, valves, heat exchangers, radiators;

2. Microcrystalline glass, instruments and equipment, medical devices, pharmaceutical equipment, and biological gene equipment;

3. High-temperature devices and high-temperature sensor components;

4. Surfaces of metallurgical equipment, molds, and casting equipment;

5. Electric heating elements, tanks, and boxes;

6. Small household appliances, kitchenware, etc.

7. High-temperature components for chemical and metallurgical industries.

Usage method

(To ensure good results, it is recommended to use it in the following way)

1.Two-component: Seal and cure in a weight ratio of 2:1 for 2 to 3 hours. The cured coating is then filtered through a 400-mesh filter screen. The filtered coating becomes the finished nano-composite ceramic coating and is set aside for later use. The spare paint should be used up within 24 hours; otherwise, its performance will decline or solidify.

2. Base material cleaning: Degreasing and rust removal, surface roughening and sandblasting, sandblasting with Sa2.5 grade or above, the best effect is achieved by sandblasting with 46-mesh corundum (white corundum).

3. Baking temperature: 270℃ for 30 minutes (Can be cured at room temperature. The initial performance is slightly poor, but it can return to normal over time.)

4. Construction method Spraying: The workpiece to be sprayed should be preheated to around 40℃ before spraying; otherwise, sagging or shrinkage may occur. It is recommended that the spraying thickness be within 30 microns. It can only be sprayed once.

5. Coating tool treatment and coating treatment

Coating tool handling: Clean thoroughly with anhydrous ethanol, dry with compressed air and store.

6. Coating treatment: After spraying, let it dry naturally on the surface for about 30 minutes. Then, place it in an oven set at 250 degrees and keep it warm for 30 minutes. After cooling, take it out.

Unique to Youcai

1. Technical stability

After rigorous testing, the aerospace-grade nanocomposite ceramic technology process remains stable under extreme conditions, resistant to high temperatures, thermal shock and chemical corrosion.

2. Nano-dispersion technology

The unique dispersion process ensures that the nanoparticles are evenly distributed in the coating, avoiding agglomeration. Efficient interface treatment enhances the bonding between particles, improving the bonding strength between the coating and the substrate as well as the overall performance.

3. Coating controllability

Precise formulations and composite techniques enable the coating performance to be adjustable, such as hardness, wear resistance and thermal stability, meeting the requirements of different applications.

4. Micro-nano structure characteristics:

Nanocomposite ceramic particles wrap micrometer particles, fill the gaps, form a dense coating, and enhance compactness and corrosion resistance. Meanwhile, nanoparticles penetrate the surface of the substrate, forming a metal-ceramic interphase, which enhances the bonding force and overall strength.

Research and development principle

1. Thermal expansion matching issue: The thermal expansion coefficients of metal and ceramic materials often differ during heating and cooling processes. This may lead to the formation of microcracks in the coating during the temperature cycling process, or even peeling off. To address this issue, Youcai has developed new coating materials whose coefficient of thermal expansion is closer to that of the metal substrate, thereby reducing thermal stress.

2. Resistance to thermal shock and thermal vibration: When the metal surface coating rapidly switches between high and low temperatures, it must be able to withstand the resulting thermal stress without damage. This requires the coating to have excellent thermal shock resistance. By optimizing the microstructure of the coating, such as increasing the number of phase interfaces and reducing the grain size, Youcai can enhance its thermal shock resistance.

3. Bonding strength: The bonding strength between the coating and the metal substrate is crucial for the long-term stability and durability of the coating. To enhance the bonding strength, Youcai introduces an intermediate layer or transition layer between the coating and the substrate to improve the wettability and chemical bonding between the two.