Water-based transparent fireproof coating (for wooden structures)

Product Description

Water-based transparent fireproof coating is a functional special coating that combines decorative and fireproof properties. It is completely transparent, environmentally friendly and water-based, and is particularly suitable for the fire protection of various wooden structures, including cultural relics and buildings with wooden structures that have already been constructed. Without damaging the structure and overall appearance of the building, it can be sprayed, brushed or rolled on the surface of the wood. When exposed to fire, the coating expands and foams to form a uniform honeycomb carbon layer, which can prevent the wood from being ignited for a certain period of time and delay the spread of the fire, thus providing valuable time for people to escape and for fire fighting.

Product Components

This product is a two-component product, consisting of Component A and Component B. When used, simply mix them evenly. The product is composed of water-based silicone resin, water-based curing agent, water-based high-efficiency flame retardant (a nitrogen-molybdenum-boron-aluminum multi-element compound), and water. It does not contain carcinogenic solvents such as benzene, is non-toxic and harmless, and is environmentally friendly.

Flame retardant principle

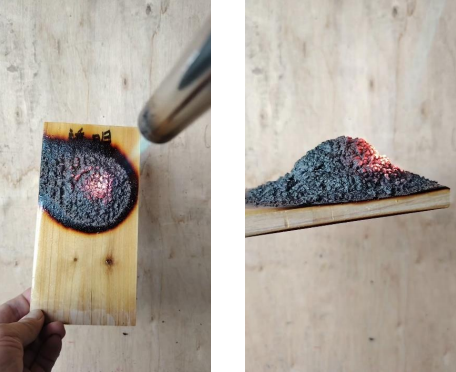

When the flame retardant coating applied on the protected substrate is exposed to high temperature or flame, the coating undergoes intense expansion, carbonization and foaming, forming a non-combustible, sponge-like carbon layer that is hundreds of times thicker than the original coating. The foam is filled with inert gases, achieving a thermal insulation effect. This carbonized layer is an excellent thermal insulator, preventing direct heating of the substrate by the flame and effectively blocking the transfer of heat to the substrate. It can also keep the protected substrate at a relatively low temperature for a certain period of time. In addition, the physical changes such as softening, melting, and expansion of the coating, as well as the chemical reactions such as decomposition, evaporation and carbonization of the additives, will absorb a large amount of heat, reducing the combustion temperature and the speed of flame propagation.

Product Advantages

- 1. Water-based paint, environmentally friendly, without any odor.

- 2. The paint film remains transparent permanently, keeping the original color of the wooden building.

- 3. The paint film maintains the fire-retardant effect permanently. With just one coat, the wooden building can be fireproof for a lifetime.

- 4. Excellent weather resistance and water resistance.

Application Prospects

Water-based transparent wood fireproof coatings have been widely used in fields such as construction, furniture, and decorative materials due to their excellent fire resistance and environmental friendliness. In the future, as people's requirements for safety and environmental protection continue to increase, the market demand for water-based transparent wood fireproof coatings will further expand. At the same time, by improving the preparation methods and formulations of the coatings, and further enhancing their fire resistance and environmental friendliness, it will help promote the development of water-based transparent wood fireproof coatings.

Usage instructions

- 1. Mix in the ratio of A:B = 2:1 (by weight).

- 2. Stir slowly in a plastic bucket to avoid air bubbles. Once well mixed, you can start applying. For spraying, you can add an appropriate amount of tap water to thin it down before spraying.

- 3. The prepared coating should be used within 40 minutes. After 40 minutes, the coating will become thicker and difficult to apply. Use the method of mixing as needed and in small amounts multiple times.

- 4. After brushing, wait 30 minutes and the surface of the coating will dry. Then, you can apply the second coat.

- 5. To ensure a good fire-retardant effect, at least two coats should be applied, or a coating amount of 500g/m2 should be ensured.

Notes for Attention

- 1. It is strictly prohibited to add any other chemicals or additives to the paint.

- 2. Workers should take proper personal protective measures during the construction process and conduct the work in a well-ventilated environment.

- 3. Clean logs can be directly applied for coating. If there are other paint films on the surface of the wood, a small-scale test should be conducted to evaluate the construction effect before determining the construction process.

- 4. The surface drying time of the coating is approximately 30 minutes. The best condition can be achieved after 7 days. During this period, rain should be avoided.