Self-polishing bottom of marine anti-fouling coating

Product Description

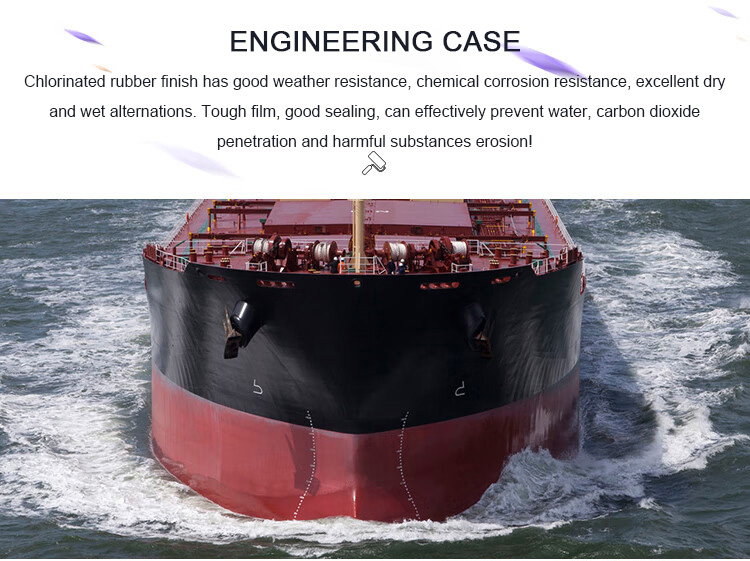

Self-polishing antifouling paint is a special coating product. It mainly undergoes a chemical reaction on the surface of the coating. As the ship sails in the water, the coating will slowly and evenly polish and dissolve by itself. This characteristic enables the ship's surface to always remain relatively clean and effectively prevents marine organisms such as shellfish and algae from attaching to the hull.

The antifouling principle of self-polishing antifouling paint is based on its unique chemical composition. It contains some hydrolyzable polymers and biologically toxic additives. In the seawater environment, the polymers will gradually hydrolyze, continuously renewing the surface of the antifouling paint, while the biologically toxic additives can inhibit the attachment of marine organisms on the newly exposed surface.

- Compared with traditional antifouling paints, self-polishing antifouling paints have significant advantages. After traditional antifouling paints are used for a period of time, the antifouling effect will gradually decline, and frequent reapplication is required. This not only consumes a large amount of time and cost but may also have a certain impact on the environment. In contrast, self-polishing antifouling paints can continuously exert their antifouling effect for a long time, reducing the frequency of ship dry-docking maintenance and reapplication.

- In practical applications, self-polishing antifouling paints are widely used in various types of ships, including merchant ships, warships, and yachts. For merchant ships, keeping the hull clean can reduce the sailing resistance and improve fuel efficiency, thereby saving operating costs. For warships, good antifouling performance helps ensure the ship's sailing speed and mobility and enhances combat effectiveness. For yachts, it can keep the hull appearance in good condition at all times and improve the aesthetics.

- With the increasingly strict environmental protection requirements, self-polishing antifouling paints are also constantly developing and innovating. R & D personnel are committed to reducing the use of biologically toxic additives in them while improving the performance of the antifouling paint to achieve a more environmentally friendly and efficient antifouling effect. Some new self-polishing antifouling paints use nanotechnology to enhance their antifouling ability and self-polishing performance by changing the microscopic structure of the coating. In the future, self-polishing antifouling paints are expected to play a greater role in the field of ocean engineering and provide strong support for the development of the marine industry.

Main features

Prevent marine organisms from causing damage to the ship's bottom, keeping the bottom clean; Automatically and quickly perform polishing to reduce the roughness of the ship's bottom, with good drag reduction effect; Does not contain organotin-based insecticides, and is harmless to the marine environment.

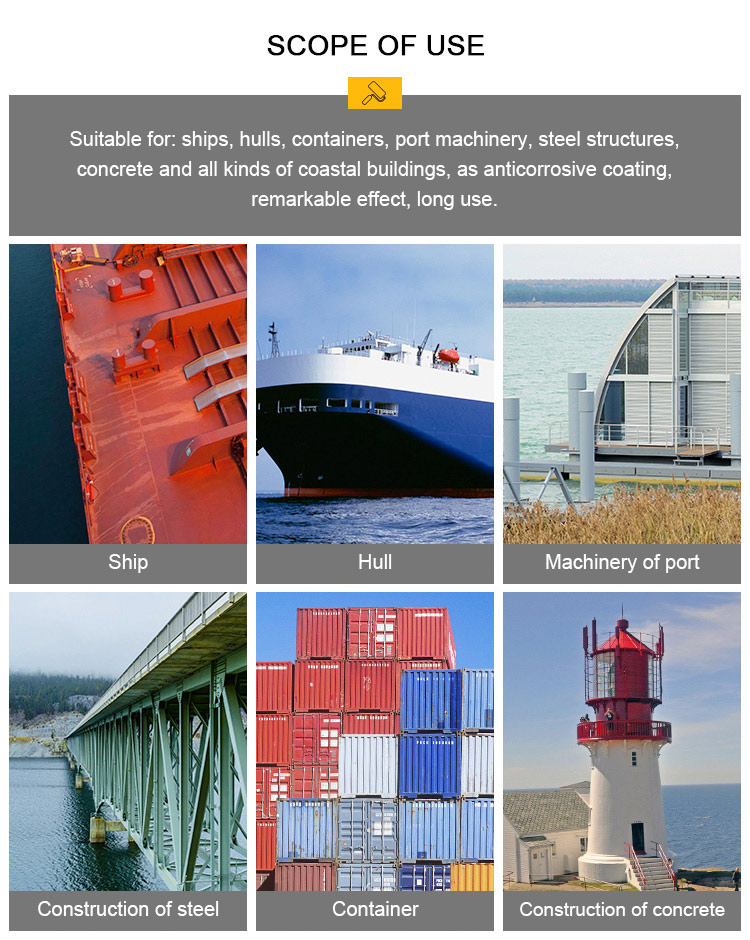

application scene

Used for underwater parts of the ship bottom and marine structures, it prevents marine organisms from attaching. It can be used as a anti-fouling maintenance paint for the bottom of ships engaged in global navigation and short-term berthing.

uses

Technical Requirements

- Surface treatment: All surfaces must be clean, dry and free from contamination. They should be evaluated and treated in accordance with ISO8504.

- Paint-coated surfaces: Clean, dry and intact primer coating. Please consult the technical department of our institute.

- Maintenance: Rusty areas, treated by ultra-high-pressure water jet to WJ2 level (NACENo.5/SSPC Sp12) or by power tools cleaning, at least St2 level.

- Other surfaces: This product is used for other substrates. Please consult the technical department of our institute.

- Post-application matching paints: Water-based, alcohol-soluble zinc silicate series primers, epoxy zinc-rich primers, low surface treatment anti-rust primers, special rust removal and anti-rust paints, phosphate zinc primers, epoxy iron oxide zinc anti-rust paints, etc.

- Post-application matching paints: None.

- Construction conditions: The substrate temperature should be no less than 0℃, and at least 3℃ higher than the air dew point temperature (temperature and relative humidity should be measured near the substrate). Generally, good ventilation is required to ensure normal drying of the paint.

- Construction methods: Spray painting: Airless spraying or air-assisted spraying. It is recommended to use high-pressure airless spraying. When using air-assisted spraying, attention should be paid to adjusting the paint viscosity and air pressure. The amount of thinner should not exceed 10%, otherwise it will affect the coating performance.

- Brush painting: It is recommended to use in pre-coating and small-area painting, but it must reach the specified dry film thickness.

Notes for Attention

This coating contains pigment particles, so it should be thoroughly mixed and stirred before use. The thickness of the anti-fouling paint film has a significant impact on the anti-fouling effect. Therefore, the number of coating layers cannot be reduced and the solvent should not be added randomly to ensure the thickness of the paint film. Health and Safety: Please pay attention to the warning signs on the packaging container. Use in a well-ventilated environment. Do not inhale the paint mist and avoid skin contact. If paint splashes on the skin, immediately rinse with a suitable cleaning agent, soap and water. If it splashes into the eyes, rinse with plenty of water and seek medical treatment immediately.