Chlorinated rubber anti-fouling paint vessels marine facilities anti-fouling coating

Product Description

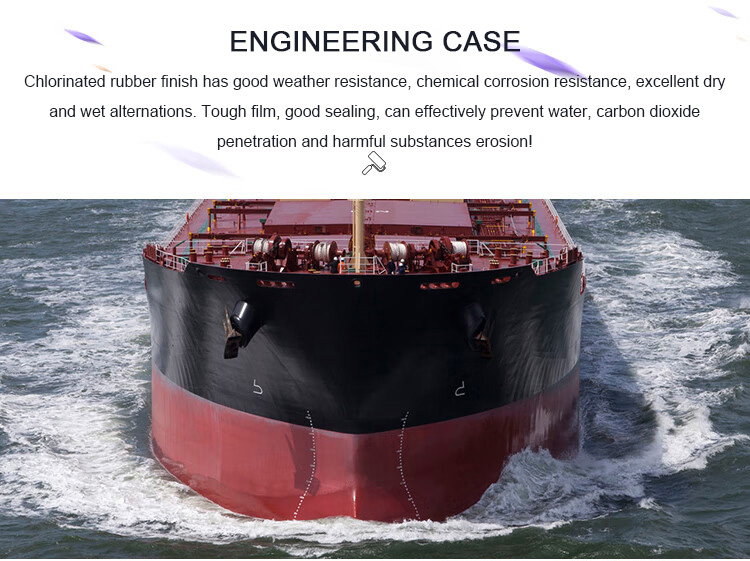

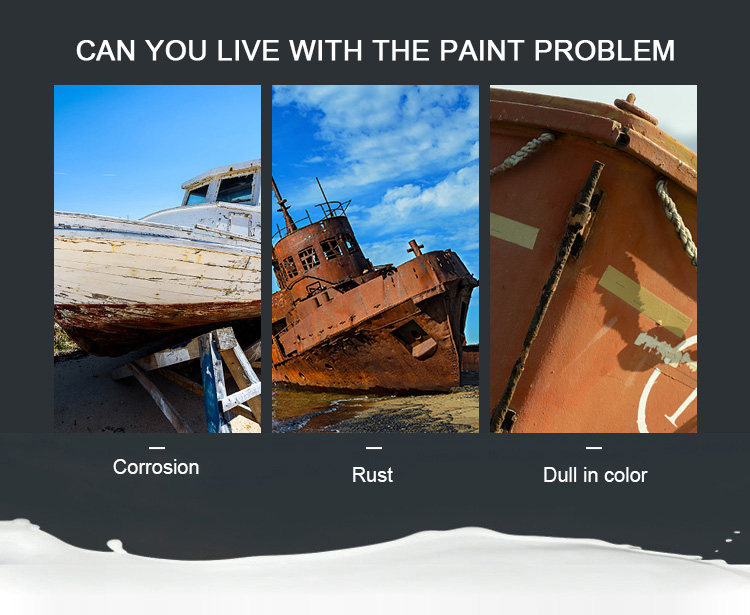

Chlorinated rubber anti-fouling paint is a functional coating primarily composed of chlorinated rubber as the film-forming substance. It is typically made by mixing chlorinated rubber, pigments, fillers, plasticizers, and solvents through specific processes. This anti-fouling paint has excellent water resistance, maintaining stability for long periods in humid environments and effectively preventing water erosion on coated surfaces. Additionally, it offers outstanding anti-fouling performance, preventing various types of dirt, algae, and barnacles from attaching to surfaces in marine environments, industrial wastewater areas, and other easily contaminated places. This extends the lifespan of objects and reduces maintenance costs due to accumulated dirt. In shipbuilding, chlorinated rubber anti-fouling paint is widely used on hulls to provide reliable anti-fouling protection during navigation. It also plays an important role in offshore platforms and underwater facilities.

Main features

The chlorinated rubber anti-fouling paint is made by grinding and blending chlorinated rubber, additives, copper oxide, pigments, and auxiliary agents. This paint has strong anti-fouling properties, can keep the bottom of the ship smooth, save fuel, extend the maintenance interval, and has good adhesion and water resistance.

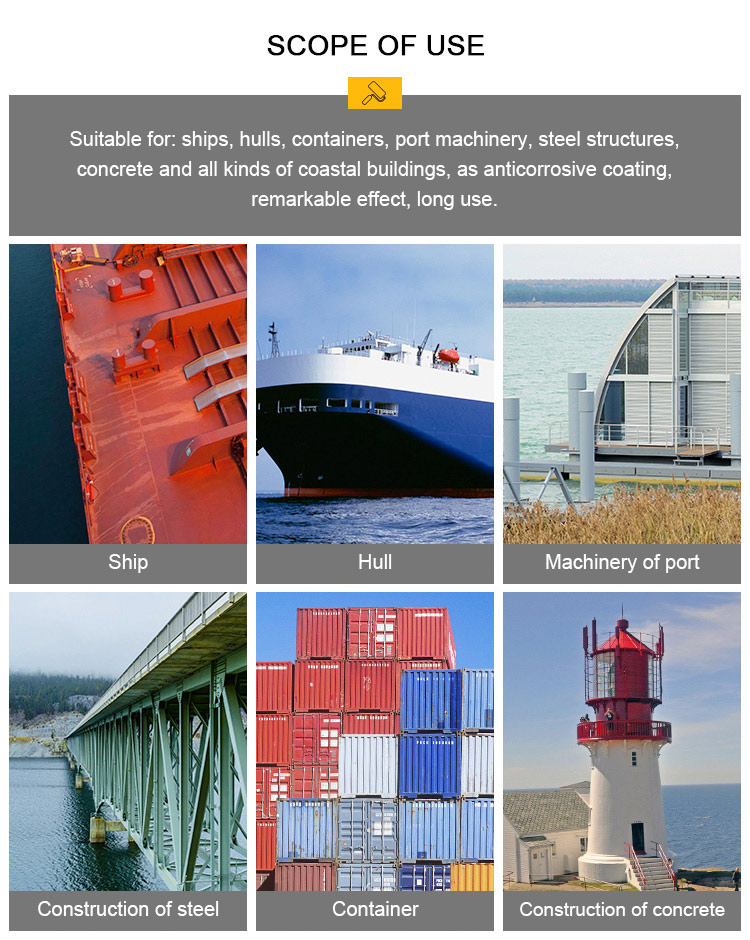

application scene

Chlorinated rubber anti-fouling paint is suitable for preventing marine organisms from adhering and growing on ships, offshore facilities, and oil platforms.

uses

Technical Requirements

- 1. Color and Appearance: Iron Red

- 2. Flash Point ≥ 35℃

- 3. Drying Time at 25℃: Surface Dry ≤ 2 hours, Full Dry ≤ 18 hours

- 4. Paint Film Thickness: Wet Film 85 microns, Dry Film approximately 50 microns

- 5. Theoretical Amount of Paint: Approximately 160g/m2

- 6. Painting Interval Time at 25℃: More than 6-20 hours

- 7. Recommended Number of Coats: 2-3 Coats, Dry Film 100-150 microns

- 8. Diluent and Tool Cleaning: Chlorinated Rubber Paint Diluent

- 9. Compatibility with Previous Coats: Chlorinated Rubber Series Anti-Rust Paint and Intermediate Coats, Epoxy Series Anti-Rust Paint and Intermediate Coats

- 10. Painting Method: Can be selected as brushing, rolling, or airless high-pressure spraying depending on the situation

- 11. Drying Time at 25℃: Shorter than 24 hours, Longer than 10 days

Surface treatment, construction conditions and safe storage and transportation

- 1. The surface of the coated object should have a complete paint film without water, oil, dust, etc. If the primer exceeds the interval period, it should be roughened.

- 2. The steel surface temperature should be 3℃ higher than the dew point temperature of the surrounding air for construction. Construction cannot be carried out when the relative humidity is greater than 85%. The construction temperature is 10-30℃. Construction is strictly prohibited in rainy, snowy, foggy, frosty, dewy and windy conditions.

- 3. During transportation, avoid collisions, sun exposure, rain, stay away from fire sources. Store in a cool and ventilated indoor warehouse. The storage period is one year (after the storage period, if the inspection is qualified, it can still be used).

- 4. The construction environment should have good ventilation conditions. Smoking is strictly prohibited at the construction site. Paint construction personnel must wear safety protective equipment to prevent inhalation of paint mist into the body. If the paint splashes on the skin, it should be washed with soap. In case of necessity, seek medical treatment.